|

|

|

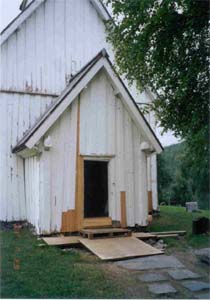

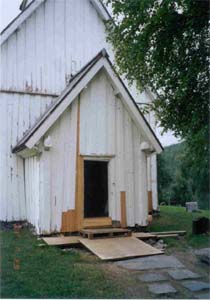

1. Entrance vestibule: The door sill had extensive rot damage.

|

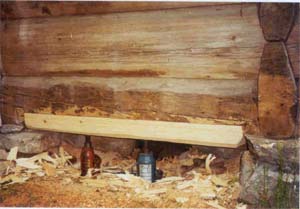

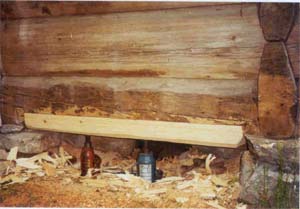

2. Entrance vestibule: Reconstructed the sill and joined it in place.

|

|

|

|

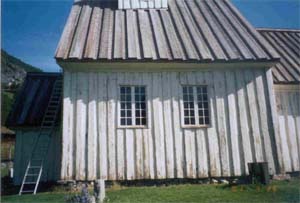

3. Entrance vestibule: Installed external panels. Photos shows that new materials were used.

|

4. Entrance vestibule: Three joists and five floor boards were reconstructed.

|

|

|

|

5. Entrance vestibule: Photo number 5 shows the new floor boards, the old ones had been replaced earlier.

|

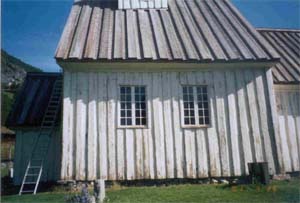

6. Entrance vestibule: Wall CC. The corner panel was lowered due to rot damage in the lower parts.

|

|

|

|

7. Entrance vestibule: Wall II was scraped and painted.

|

8. Stairs: The flagstone in front of the door is the original, the flagstones lie in crushed rock.

|

|

|

|

9. Stairs: The flagstone in front of the door is the original, the flagstones lie in crushed rock.

|

10. Stairs: The flagstone in front of the door is the original, the flagstones lie in crushed rock.

|

|

|

|

11. Nave Gable - end walls: Wall III. Dismantled external panels.

|

12. Nave Gable - end walls: Wall III. Rot damaged sill was bunged up (inserted) with new wood. The foundation wall was laid in crushed rock.

|

|

|

|

13. Nave Gable - end walls: Wall III. Rot damaged sill was bunged up (inserted) with new wood. The foundation wall was laid in crushed rock.

|

14. Nave Gable - end walls: Wall III. The photo shows the use of new wood materials - scraped and painted.

|

|

|

|

15. Nave Gable - end walls: Wall III. Joists were impregnated against parasites during the last restoration. There is no rot damage on these.

|

16. Nave Gable - end walls: Wall III. Attached single panels with hand-forged nails. Scraped and painted.

|

|

|

|

18. Nave Gable - end walls: Wall Y. Dismantled external panels. Rot damage was found on sill and corner.

|

19. Nave Gable - end walls: Scraped and painted Wall CCCC.

|

|

|

|

20. Nave Gable - end walls: Wall CCC. Dismantled the foundation wall and external panels. The sill was rot damaged.

|

21. Nave Gable - end walls: Wall CCC. Dismantled the foundation wall and external panels. The sill was rot damaged.

|

|

|

|

22. Nave Gable - end walls: Wall CCC. The sill was bunged up with new material and the wall was replaced.

|

23. Nave Gable - end walls: Wall CCC. External panels were replaced. Photo shows the use of new materials. Scraped and painted.

|

|

|

|

27 og 28. Chancel: Wall VI. Dismantled the foundation wall to examine the joists and floorboards. The joists were lying in dry boggy soil with minor rot damage. The joist foundations were straightened up. The foundation wall was replaced on crushed rock. Scraped and painted.

|

|

|

|

29. Chancel: Wall VIII. Hand-forged nails used to tighten lose panels. Scraped and painted.

|

30. Chancel: Wall YC. Dismantled external panels. Bunged up rot damaged sill with new material.

|

|

|

|

31. Chancel: Wall YC. Rot damaged sill.

|

32. Chancel: Wall YC. Rot damaged sill.

|

|

|

|

33. Chancel: Wall YC. Photo shows use of new materials. Scraped and painted.

|

34. Chancel: Wall YC. Photo shows one panel fixed with wooden nails.

|

|

|

|

35 og 36. Chancel: Wall YC. Some panels were turned around. There were visible evidence of tar treatment and use of wooden nails.

|

|

|

|

40. Bell tower: The detached scaffolding was built by Ivar Pedersen, Tveit.

|

41. Bell tower: The church bell tower was scraped and painted. Photo shows use of new materials.

|

|

|

|

42. Bell tower: The church bell tower was scraped and painted. Photo shows use of new materials.

|

43. Roof: There was large rot damage on the roof panels. There were no damage to the nailing strip. The ridge of the roof was covered with sink (replaced existing sink). The same pattern for drainage was used as before.

|

|

|

|

48. Spire: The shingles were shaped with axe and impregnated on all sides with tar prepared in charcoal kiln.

|

49. Spire: The tar was delivered by Fortidsminneforeningen (Organisation working for the protection of ancient artefacts). The tar was heated in a water bath before use. The spire was tarred with 4 strokes.

|

|

|

|

50. Spire: The top row of shingles was reused. See appendix 2 for a sketch of the weathervane.

|

|

|

|

|

51. New shingles: Standing spruce trees were selected during sap time. The trees had been growing very slowly. The shingles were cut perpendicularly.

|

52. New shingles: The shingles were dried in room temperature (+25°C). Moisture was monitored during the drying period.

|